The Main Principles Of Underwater Welding

Wiki Article

The Definitive Guide for Smaw

Table of ContentsWelders Near Me Fundamentals ExplainedThe Buzz on Cold WeldingSpot Welder - An OverviewIndicators on Welding Shops Near Me You Need To KnowThe Single Strategy To Use For Welding Shops Near MeMore About Underwater WeldingThe Definitive Guide to Spot Welder

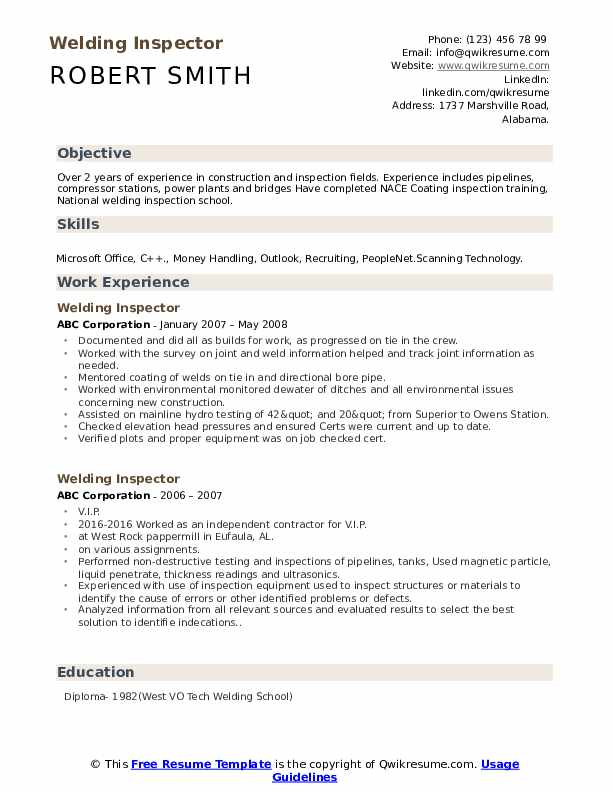

Aesthetic inspections look for flaws in the weld such as fractures and pits. The inspector uses magnification to discover problems that prospective damage the toughness of the joint. Assessors determine welded products to guarantee that they satisfy specifications for dimension. The certified weld assessor makes use of stress and anxiety tools to put stress and anxiety on weld joints.Welding examiners record the outcomes of examinations as well as welding examinations. An university education and learning is not needed for the majority of welding or welding assessment positions, however an associate level in welding innovation can enhance the opportunities of landing a job.

Automation does not lower the demand for evaluation.

Something went wrong. Wait a minute as well as attempt once again Attempt once again.

The Mig Welder Diaries

Elderly Personnel Engineer, National Board This article was initially released in the Fall 2009 National Board BULLETIN as the very first of a two-part series. Keep in mind: The function of this article is to provide assessors with a general knowledge of weld examination.While not imperative, the inspector needs to discover to read common weld icons such as the AWS icons. At least, the examiner needs to always carry a recommendation overview to translate weld signs. Having assessed all this info beforehand, the assessor will be prepared to identify any type of troubles as they establish instead of after-the-fact.

The maker or repair company (certificate holder) has suggested at work drawing that a weld joint is to be prepared with a 60-degree bevel and root void of 1/16 inch. Unless the bevels are crushed on precision equipment, it is doubtful they will certainly achieve a specific 60-degree bevel as shown.

The nozzle axis is 90 to the level head, and also the add-on weld consists of a 3/8-inch fillet weld. The inspector can quickly measure the fillet weld to make certain compliance.

Cold Welding - Truths

This instance comes to be also much more important if the nozzle is set up at an angle apart from 90 (Fig. 3). Using the same nozzle add-on instance as defined above, let's consider the weld joint preparation. The certification owner has defined a 45-degree bevel around the area of the hole in the level head and also the vessel shell.4). The curved shell will offer even more of an obstacle. The assessor will have to determine if the certificate owner is referencing the bevel from the upright axis of the nozzle (Fig. 5) or from the variable reference airplane of the rounded covering (Fig. 6). When bevels are prepared with a cutting torch and do with a mill, it is extremely challenging to maintain a specific angle.

Assessors are trained to believe just what their eyes tell them; however when the inspector can not see the internal surface area of the tube, it ends up being tough to approve that situation. If the tube ends are effectively prepared (beveled) as well as a certified welder is making use of a qualified welding procedure, the chances are really good that the welds will be complete infiltration.

look at this web-site One "warning" to a possible problem would be if the assessor observes that the tube ends have not been beveled. The inspector must instantly ask the certification holder about this circumstance. It can be as basic as the certification owner having actually simply not performed that action in the procedure yet, or maybe as negative as his/her having actually attempted to conserve money and time by not beveling completions.

Everything about Arc Welder

The welder additional resources would require to begin with a big root gap and after that be really cautious not to "push through" excess filler steel to create weld build-up on the within the tube.1, provision 6. 1, requires welding inspectors of all degrees to pass an eye evaluation, with or without corrective lenses, to prove near vision skill, in at the very least one eye, on Jaeger J2 letters or smaller at a distance not much less than 12 inches. A color perception examination and a contrast distinction shades of gray examination need to be taken, but the company establishes the acceptance for these 2 examinations based on the weld exam being done.

I keep in mind helping a foreman that was about as arrogant and also egotistic as they come. He treated simply regarding everyone he met derision. He 'd just been advertised to foreman and was trying to be a ruffian. We were servicing a quite high high-rise, his first "big task." That's where "Mr.

He informed the inspector he hop over to here required to rush and also get out of our means the same method a drill sergeant would tell a new recruit to come down and also do push-ups! The inspector didn't claim a word; he simply responded and also strolled off. The following early morning when we reached the job there was a sea of red around the floor we were functioning on.

It had not been that the welds were negative; they simply were "technically" not up to requirements. Our welding examiner was not a delighted camper. Our ruffian boss was nearly in splits! Luckily for us, we were able to speak with the examiner and also clarify what an idiot our employer was as well as that he was not promoting our staff.

Some Ideas on Underwater Welding You Should Know

Impact examination. Etching. Devastating are typically utilized in educational testing, shop screening, and also tests welders take to get certified or hired on at a jobsite.The responsibilities are divided right into 3 major phases; Confirm that the material is in accordance with attracting/ WPS recognized as well as mapped to a test certification in ideal condition (without damage and also contamination) WPS is authorized and also readily available to welders (and examiners). Welding equipment is in suitable problem and adjusted as appropriate.

Recognition of welders qualification for every WPS to be made use of as well as all welder credentials certificates stand. Welding consumables to be made use of are-as specified by the WPS-stored/controlled as specified by the QC treatment. Joint fit-ups are in accordance with WPS/ illustrations Tack welds are appropriate per requirements, code or WPS.

The minimum temperature level for Preheat (if needed) is in accordance with WPS. Make certain weather appropriate/ adhere to Code (conditions will certainly not influence welding) when on-site/ field welding. Welding process need to remain in accordance with WPS. Preheat (if called for) minimal temperature level is being maintained in conformity with WPS.

The Basic Principles Of Smaw

Ensure all reports/records are completed as well as collated as called for. 1 Program note.Report this wiki page